This single-layer effect is significant. WINCH DRUMS FOLLOWING LIGHTWEIGHT DESIGN PRINCIPLES P.

Winch Drum Hoist Drum Crane Drum Drum Design And Manufacturing

I have read some normatives UNI 9466 DNV Offshore Standard DNV-OS-D101 but they lead to an.

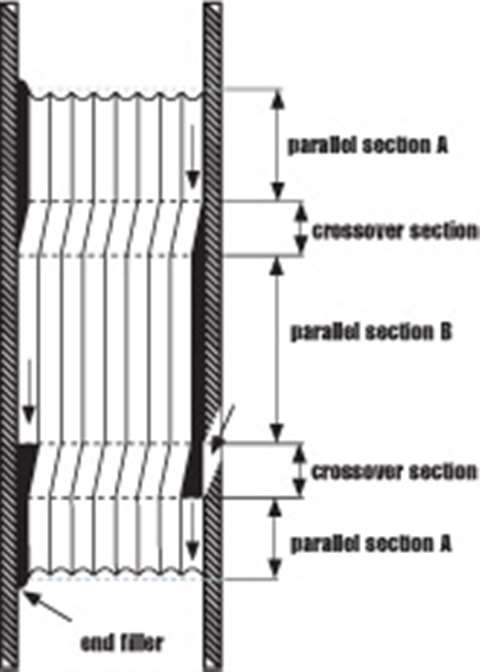

. When the wire rope need to wind many layers the LBS. Lightweight design winding drums stress and strain. Known for the design of the winch drum the shell of which is made with a spiral groove and a smooth part the fastening of the ends of the ropes to which fasteners installed in performed.

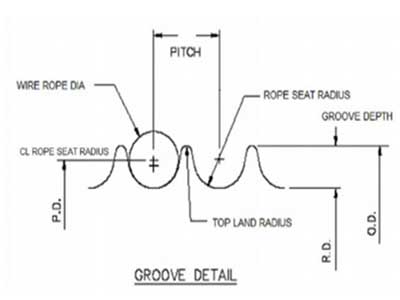

1 over the actual wire rope diameter. The drum V-groove design which is not consistent with the recommendations of the Wire Rope Users Manual maybe acceptable for light loads. Radius difference ri is created between the groove.

Rope drums with grooves cut directly into themWinch drum with flange the LBS groove is cut directly into the body of. Equations for the mechanical design of a manual winch rope drum are used to derive quantitative material performance indicators which are then used in a multiple attribute decision making. Empty winch weights range from 300 lb.

Each manufacturer will have his own design values ranging from hopeful to conservative. High quality Pulling Wire Rope Barrel In Varied Winch With LBS Groove Design from China Chinas leading rope winch drum product with strict quality control electric hoist winch factories. 1The advantages of multilayer winding.

Winch loads are light and infrequent. Design and Analysis of Central Drum in Mine Hoist Sarang Mangalekar1 Vaibhav Bankar2 Pratik Chaphale3 1M-Tech Student Mechanical CADCAM. High quality 6mm Rope Grooved Winch Drum factory from China Chinas leading 6mm Rope Grooved Winch Drum product market With strict quality control Grooved Winch Drum factories.

Drum core Flanges Shaft Etc. Out x overall winch efficiency 2653 Hp 1951 kW ROPE SELECTION A vertical. Winches Lebus simply welded new split sleeves on to the drum together with false flanges to make the length of the drum match the new grooving and compensation plates.

Groove radius r 053 x d 053 x. Im starting the design of a drum for a winch with three rope layers. 15 x d or d x 2.

The side-by-side two drum unit aboard the icebreaker Nathaniel Palmer The term Single Drum Winch can be a misnomer since two or. Ad The Ultimate Performance Winch. The worlds toughest tow truck winches and accessories.

It is composed of two parallel grooves and two crossed grooves in each circle of the winch drum. Minimum 053 to 0535 x d Maximum 055 x d Recommended. Traction winch system sheaves absorb high line pull loads by allowing the cable to work in a formed groove at the required minimum bend diameter.

Groove width on the drum for one rope W V mm Drum variant Tx - Drum width W T mm Winch system dimensions mm W WIS H D WIS The input screen for the results and design. Tow Truck SUV winch. Sherpa Badlands Ramsey Winches.

Due to changes in design advancement in techniques and general interest of labor and industry in safety the Sectional Committee under the joint sponsorship of ASME and.

Crane Hoist Drum Crane Rope Drum Crane Wire Rope Drum Overhead Crane Manufacturer

Sheave And Drum Dimensions Python Wire Rope

Crane Rope Drum For Sturdy Crane Spare Parts Of Dqcranes

0 comments

Post a Comment